RAMCO Masking Wax Removal System

This Case History covers a system built for the removal of masking wax. Masking wax is used in parts manufacturing, overhaul and repair, turbine and metal finishing, as well as orthopedic implant, surgical instrument, and medical device component processing to prevent contamination from acid, alkaline and plating solutions and the debris from air plasma spray, HVOF, peening and grit blasting.

Wax Removal System

An alternative low VOC wax removing solvent was successfully used for the process. The results proved that the dynamic combination of chemistry, platform oscillation, and solution turbulation safely and effectively removed all traces of masking wax from internal and exterior surfaces of the parts. And the total cycle time was drastically reduced.

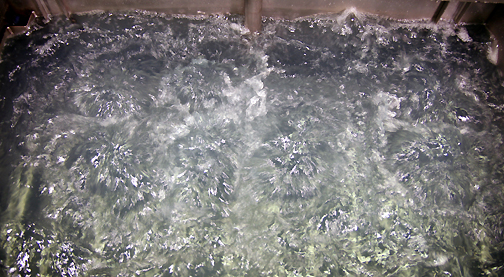

The heart of the RAMCO system is the adroit use of an elevator within each processing chamber. The elevator is used to transport work into and out of the chamber but its most important function is to continuously move the work within the processing zone. It is this dynamic function that allows RAMCO systems to achieve superior results in washing, rinsing and drying. We call this Dynamic Flow Combination. The effect of Dynamic Flow Combination is better coverage of component surfaces (minimizing standing waves and/or part shadowing) producing more consistent results and accelerated processing times.

The line runs in a left to right. After stripping, the parts are easily transferred to the rinse stage. Rinsing of the parts after stripping is necessary to remove any residual wax removal chemistry. This step is easily accomplished with hot water, platform oscillated and turbulation.

Turbo Action

The entire process now takes less than half the time of the old technology, uses no hazardous chemistries, and operates in a semi-automated fashion, saving the customer huge amounts of labor.